Fabricating Ability

In 2008, Lingyun established a modern Industrial Park in Wuhan, covering 75,000 square meters, with world advanced fabrication center, PVDF coating production line, curtain wall design center and a testing center. Its annual capacity for design, fabrication and engineering of curtain wall has reached 3,000,000 square meters.

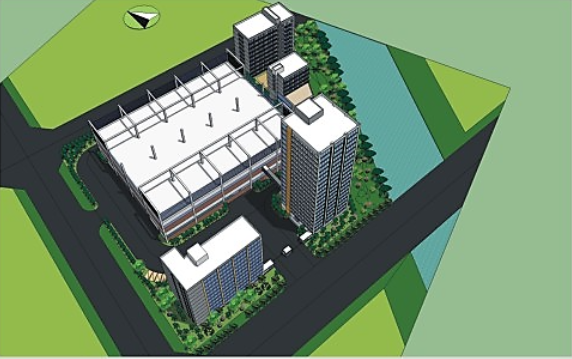

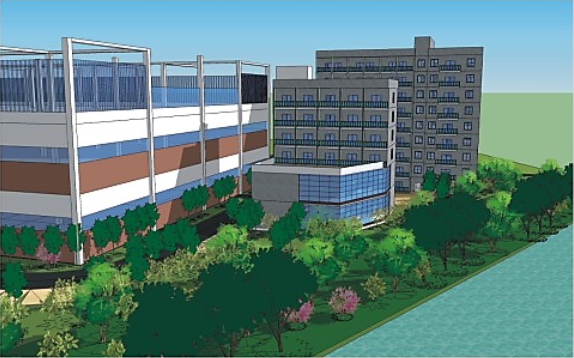

Guangzhou Fabrication Base

Guangzhou headquarters base of Wuhan Lingyun will be established in Baiyun District of Guangzhou City covering an area of 19,505m2. It plans to build an area of 13,000m2 fabrication plant for curtain wall production, a 7,000m2 R&D office building, and two buildings for ancillary facilities covering total area of 7,000m2 in the first phase.

In the second phase, we plan to build another 12,000m2 R&D repairing plant. In this plan, total building area is 39,000m2 with total investment of CNY 88 million, including infrastructure construction of CNY 55 million, equipment of CNY 15 million and land investment of 18 million.

Plate's Fabrication Line

Plat'es fabrication line, with an annual plate fabrication ability of 600,000 square meters, is equipped mainly with shearing machine, bending machine, laser cutting machine, plasma cutting machines, CNC punch press, slotting machine, pull slot machine and welding machine. In addition, it can realize exact cutting, bending and welding etc. to plates with arbitrary shapes such as rectangular, round and oval and so on. The maximum size for finished products can reach 3,000*12,000.

Stainless Steel Notching Machine V-6012

- Origin: Japan

- Notchine for panel materials including stainless steel panel, aluminium panel, honeycomb panel, plank, etc.

- Depth accuracy ± 0.05mm/m

- Largest processing length 6 m

- Maximum auto material input 25 m/min

- Distinct angle after notched materials are bent and brings strong vision impact

- Solve the problem of direct bend

- Facilitate the follow-up processings, for example:

Some materials can be notched, pre-bent and painted before shaping - The material with big thickness can be notched to prevent cracks during bending

CNC Plasma Cutting Machine: Magician

- Cutting Material: stainless steel, carbon steel, aluminium panel

- Effective cutting width 3,000 mm, track distance 4,000 mm

- Effective cutting length 12,000 mm, track length of 15,000 mm

- Plasma cutting thickness 1-32 mm, cutting torch range 200 mm

- Empty speed of 24,000 mm / min, cutting verticality ± 1.5 degrees

- Cutting speed 0-12,000 mm / min, position accuracy ± 0.15 mm / full length

- Repeating accuracy of ± 0.15 mm / full length, diagonal tolerance less than ± 0.5 mm within 4m x 10m

- Machine running straightness ± 0.3 mm

- Plasma height control accuracy ± 0.2 mm

- A high degree of control accuracy of plasma ± 0.2 mm (arc voltage control), cutting section roughness Ra12.5

- Working gas: oxygen, nitrogen, compressed air

- Working environment -10°C ~ 45°C

Aluminium Extrusion Fabrication Line

Aluminium extrusion fabrication equipment is mainly brought in from Germany Yale Company. With an annual fabrication ability of 30,000 tons, this production line is comprised by aluminium feeding machine, single head saw, saw double-headed, two-dimensional milling machine, three-dimensional milling machine, three-axis CNC milling machine, five-axis CNC milling machine, hydraulic angle molding machines, profile bending machines, etc.

Profile Machining Center Sbz 130

- Origin: Germany <Yale (Elumate) Corporation>

- All computer-controlled, three-axis linkage, five directions of the drilling, milling

- Maximum length 9 m, processing length 7,080 mm, width 480 mm, height 325 mm

- Positioning accuracy of 0.1 mm/m

- Maximum processing speed of 45 m/min

- High efficiency, accuracy, repeatability

Dg142 + E355 Germany Origin --- Double-Head Saw

- Main function: requirement of the procession orient precision ± 0.1 mm / 1,000 mm

Six-Drilling Machine

- Main function: drill from single or multipoint and mill processing

Thermal Break Profile Compounding Machine

- Origin: Germany

- Used for automatic compounding of thermal break profile

- Allocated with specific checkout equipment

- Compounding speed: 60 m/min

Coating Line

With an annual coating ability of 2,000,000 square meters, Lingyun's coating line is the most advanced and largest one in China. The total line is more than 240 meters. The product path is 1.5 m in width and 2.7 m in height. It can realize coating for trans-normal size products of 1,500*2,700*9,000.

PVDF Spraying Production Line

- National first-class automatic pre-processing and PVDF production line

- Re-processing according to aluminium processing techniques from HENKEL Germany

- Deionized water equipment with a daily 50 tons productivity

- Static dust removal device

- Facilities are equipped according three bakes and one coating techniques, with 6 big-sized automatic coating rooms

- Automatic air exchange, temperature control and air filtration in the coating room

- 10 sets of static high-pressure magnetic sprayer (0-101KV) and supporting system from PPH308, SAMES of France

- 4 sets of RANSBURG manual sprayer from Japan

- 1 set of automatic recognition system for work piece

- 1 set of channel type oven, size 45 m * 1.5 m, temperature control range 25-280°C

- Reburning system for nocuous gas

- A set of automatic sewage disposal equipment

Testing Equipment of PVDF Coating Line

- A set of pre-processed liquid test device

- A set of coated product quality inspection device

- A set of Germany "QUANIX7500" coating thickness inspection device

- A set of standard adhesiveness test

- A set of GADNER portable color inspector

- A set of Germany "MICRO-TRI-GIOSS" inspection device

- A set of "DATAPAQ" furnace temperature measuring and recording device

Plate Assembly Line

Lingyun has three plate assemble lines, and each line is 70 m long, with 1.3-1.5 meters spacing between two chains. The moving speed of assembly line is 1.5 m per minute, and can be controlled if necessary. The assembly lines can carry 10-15 plates simultaneously, and the annual assembly quantity is 300,000m2. It consists of four working areas of frame assembly, glass hoisting and installment, sealant application and post processing.